Design Theory:

Material Research

Material Research

Project Length: 2 Weeks

This project consisted of choosing a by- product or waste material, in this case sawdust, to explore its possible properties through various experiments. User experience/ feedback also played an important role as it would influence the next stages of experimentation.

Tools Used

The tools and ingredients used throughout this project are as follows:

Cornflour, Tapioca Flour, Sugar, Vinegar, PVA glue, Glycerine, Red and Blue Food Colouring, Aluminium Foil, a Tablespoon, Teaspoon, Stanley Blade and a Lighter.

Cornflour, Tapioca Flour, Sugar, Vinegar, PVA glue, Glycerine, Red and Blue Food Colouring, Aluminium Foil, a Tablespoon, Teaspoon, Stanley Blade and a Lighter.

The Material

For this project I will be looking at the waste product sawdust. Specificaly pine sawdust which properties include absorbency, a fresh scent and when mixed with glue and resin's etc. can be used to make engineered woods such as MDF.

User Feedback 1

After some quick experiments that I could do at the time I referred to my tutor to show what I had completed so far but also to get a sense of what areas of experimentation I have missed and finding new direction. And so it was suggested that I look at ways to change the form of the material and begin mixing it with ingredients like bio- plastic, caramelised sugar and so forth.

Bio Plastic

When I found that Bio Plastics can be made with simple ingredients I thought this would be a great opportunity to combine it with sawdust to find new insights and properties.

Initial Bio Plastic Experiments

Recipe--->

1 Tablespoon of Cornflour

4 Tablespoons of Water

1 Teaspoon of Glycerine

1 Teaspoon of Vinegar

Findings: Very strong similar to leather, allows light to travel through.

Adding sawdust into the mixture helps bind the ingredients together however when it dries the material breaks apart into separate pieces but retains a rubber quality.

A New Recipe

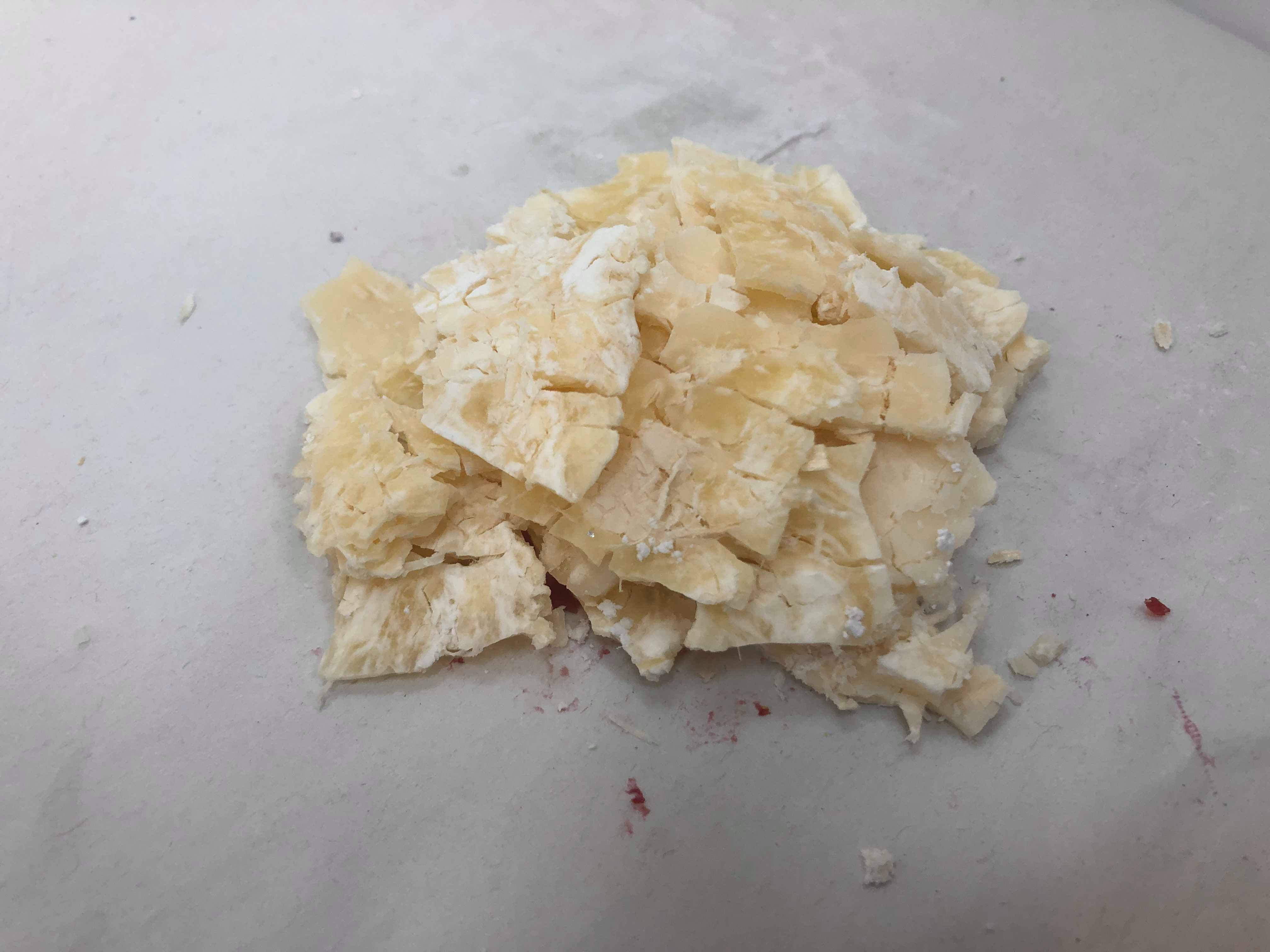

When looking at bio- plastic mixtures I came across another recipe with a different mixture, mainly consisting of cornflour, water but with oil. And so I tried making it without any sawdust to see what the result was, which as you can see is similar to a crumbled meringue. And when I added sawdust into the mixture it still cracked when drying and broke into larger chunks as the sawdust was bound to the ingredients.

Recipe--->

2 Tablespoon of Cornflour

2 Tablespoons of Water

1 Teaspoon of Oil

After seeing the result of mixing the sawdust with the bio- plastic in the pan I decided to try a different approach and instead I would create the bio- plastic, pour it onto a flat surface, add the sawdust, mix it and then form the material round a pre made form and see if it could hold shape. And as you can see from the images below that the results were successful and it can take on detail too.

Possible applications for this material could be plant pots as the material has the strength to hold the compost and plants for it but also the sawdust will be good for the plants itself.

Moulding

At this point I wanted to see if the bio- plastic from the original recipe could be moulded into a form and keep said form and so once I had mixed the ingredients together and added the sawdust I compressed the material into a mould and allowed for it to dry. The result is a tough compressed mould with a relatively smooth texture.

Recipe for Mould 1 --->

1 Tablespoon of Cornflour

4 Tablespoons of Water

1 Teaspoon of Glycerine

1 Teaspoon of Vinegar

A handful of sawdust mixed into the pot.

Recipe for Mould 2 --->

2 Tablespoon of Cornflour

8 Tablespoons of Water

2 Teaspoon of Glycerine

2 Teaspoon of Vinegar

A handful of sawdust mixed into the pot.

Possible Applications include: stools, a alternative to cork, place mats, coasters etc...

Food Colouring

Another experiment I wanted to try was adding the food colouring that I had used before but mix it with the bio- plastic and sawdust to see if it would interfere in any way. And aside from obviously changing the colour the food colouring altered the consistency of the material as when it cures the bio- plastic had a jelly-like structure.

Recipe --->

1 Tablespoon of Cornflour

4 Tablespoons of Water

1 Teaspoon of Glycerine

1 Teaspoon of Vinegar

2 Teaspoons of Red Dye

A handful of sawdust mixed into pot

Recipe --->

1 Tablespoon of Cornflour

4 Tablespoons of Water

1 Teaspoon of Glycerine

1 Teaspoon of Vinegar

2 Teaspoons of Blue Dye

A handful of sawdust added after mixing.

Possible Applications include: builders putty or any putty adhesive.

User Feedback 2

My second user testing involved three subjects, I presented the material samples in front of them like I have done with this exhibition and asked them: What samples stands out to you? Do you notice a difference between the raw sawdust and refined sawdust? Do you like the smell of the refined sawdust? And finally, do you like the smell of the sawdust mixed with bio- plastic?

What the users stated was that they found the material with red food colouring the most striking. That they could see and feel a difference between the raw and refined sawdust. And that they preferred the smell of the untouched sawdust compared to the bio- plastic mix as the vinegar left an undesirable smell.

Adding Strings to the Mix

By putting bass strings in to the sawdust bio- plastic mix and letting it set allowed for the material to bind to the strings allowing them to become one it also allows you to lift the sample by strings without fear of the material crumbling away.

Recipe --->

2 Tablespoons of Starch

8 Tablespoons of Water

2 Teaspoons of Vinegar

2 Teaspoons of Glycerine

Add the bass strings once the mixture has been put in a mould to allow the material to cool and form around the strings.

Possible applications include being a replacement to reinforced concrete as the materials bonds happily to the stainless steel strings.

Caramelised Sugar

After many iterations of mixing the sawdust with bio- plastic I decided to try using caramelised sugar to see if it had a different effect compared to the previous experiments.

I realised that I wouldn’t be able mix the sawdust in with the sugar when baking as the viscosity of the sugar wouldn’t allow proper mixing and so instead I would pour the sawdust into the mould then pour the caramelised sugar on top.

However as I had a substantial amount of sugar left I decide to use another mould and pour the sugar in first, then add a handful of sawdust and then pour the rest of the sugar into the mould. The result are a tough but sticky material that allows light to pass through highlighting the various sawdust particles.

Recipe --->

4 Tablespoons of sugar

1 Tablespoon of water.

Handful of sawdust added after the mixture is complete.

Possible applications could be an alternative replacement to glass specifically privacy glass, could also be used as a material to help diffuse light or even be used for lamp shades.

Using Wall Filler

Recipe --->

4 Teaspoons of Wall Filler

1 Handful of Refined Sawdust

Mixing wall filler with sawdust yields interesting results as the material becomes brittle. I thought that by adding sawdust the material would be tougher and would have had similar qualities to the reinforced bio- plastic with bass strings.

Nevertheless it was still a useful exercise.

Nevertheless it was still a useful exercise.

User Feedback 3

After the various experiments I conducted I then decided to do user testing with my peers to see if there was any insights that could be gained. And so the questions I asked were:

What Sample Stands Out To You and Why?

The majority of the response was that the bio- plastic mix with red food dye was the sample that stood out due to its colour and “springy” texture.

Does The Sample Remind You Of Anything?

From the feedback the user stated that most of the samples reminded them of food based objects such as caramel, gelatine, pudding, jelly, sugar glass and so forth.

Are You Surprised With Any Of The Samples?

What some users said was that they were surprised by how much the material has changed from its original form. And that hey were also surprised at how “squishy” some of the samples were when they had cured/ dried.

Any Additional Notes?

Lastly the users stated that some of the samples smelled of nostalgia. That they would like to see the samples look more expensive and that the colours and mixture of ingredients/ materials made it look like food.

Final Presentation

After the experimentation was completed I set out the results on a table in a more organised manner and allowed my peers to interact and write down what they thought of each sample.

The overall majority of users agreed that it was remarkable to see the sawdust change from it original form when mixed with materials such as bio- plastics and caramelised sugar. The majority of users also noted that the material took on a more edible/ food based look to it.

Reflection

This two week project reignited my need to experiment with materials as well as forms more as I had not given my self the opportunity to do this prior to this project.

So with that in mind I took it upon myself to catch up and try every pathway when exploring the waste material sawdust as well as applying this experimentative mindset to future projects as the results could lead to more interesting and enhanced developments.

If you would like to know more about this project

Drop me an email, lets talk

--->

c.sferguson25@gmail.com